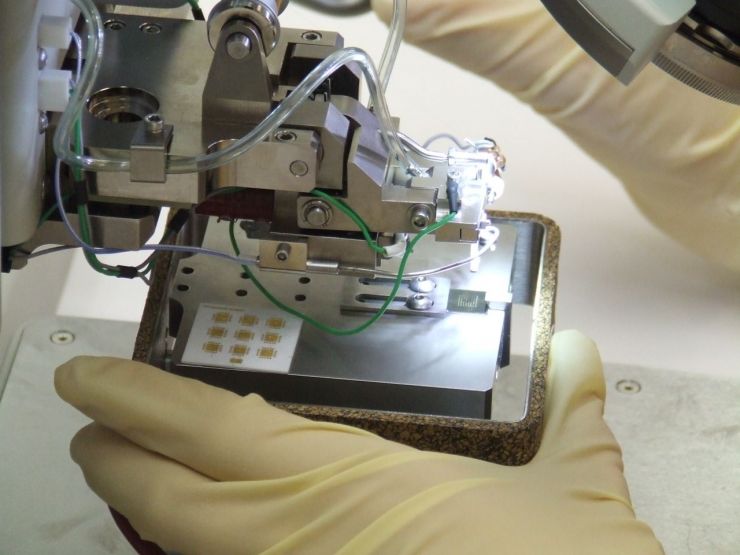

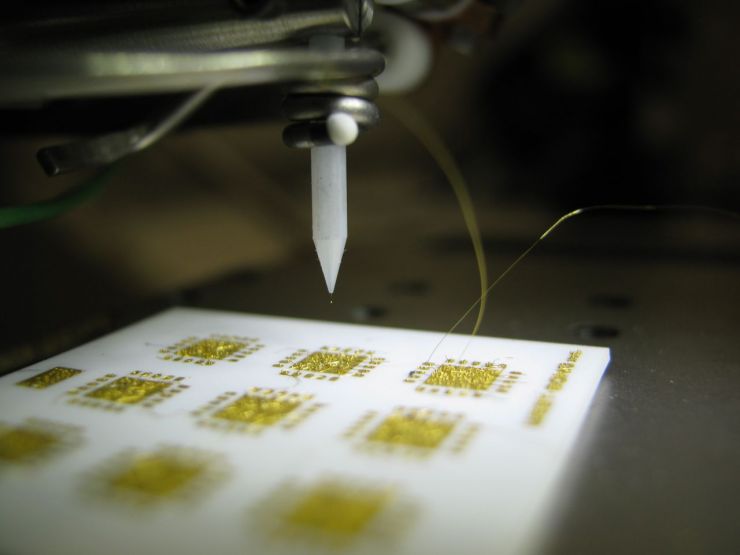

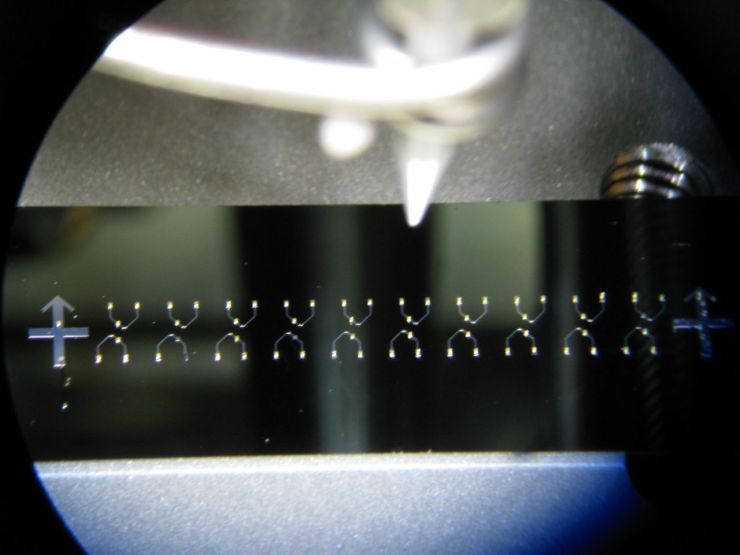

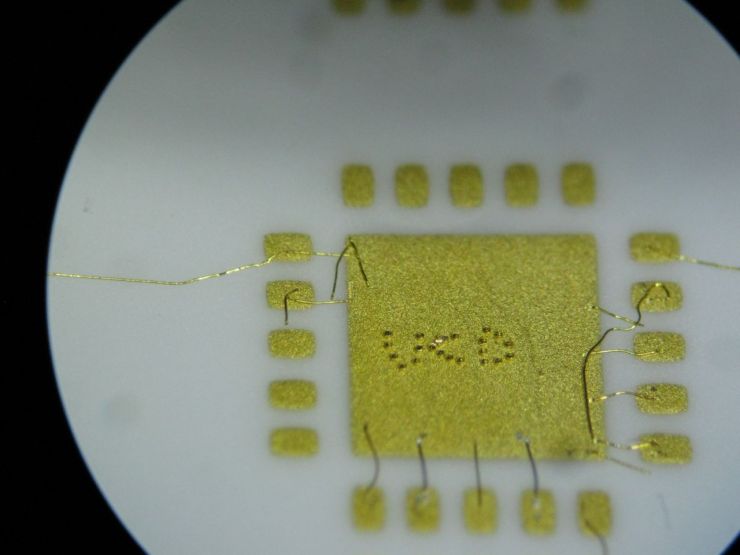

The Westbond Manual Wire Bonder allows us to very accurately place gold studs on a substrate. This machine is used to create gold stud bumps with 1 mil or 0.5 mil gold wire for all gold stud work done in the lab.

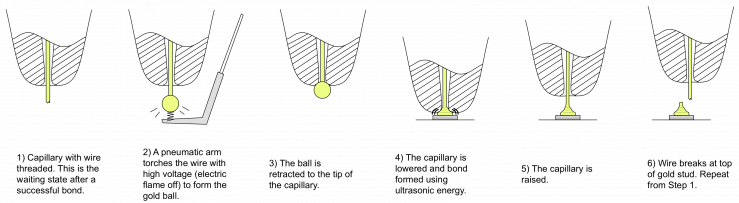

The gold studding process:

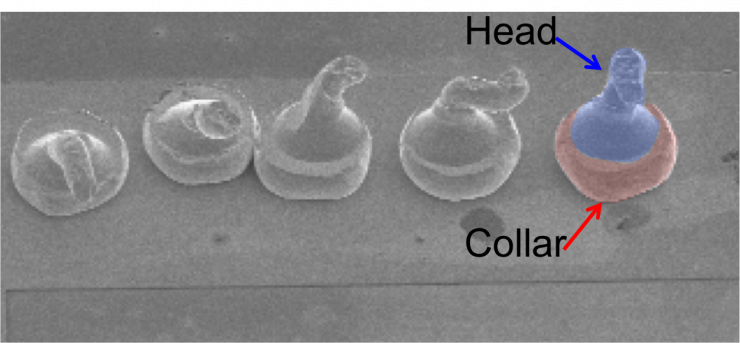

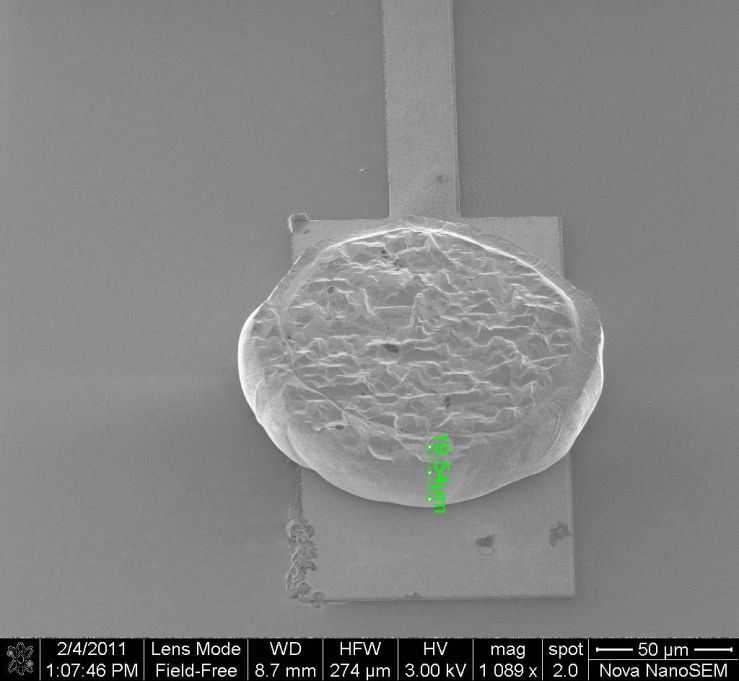

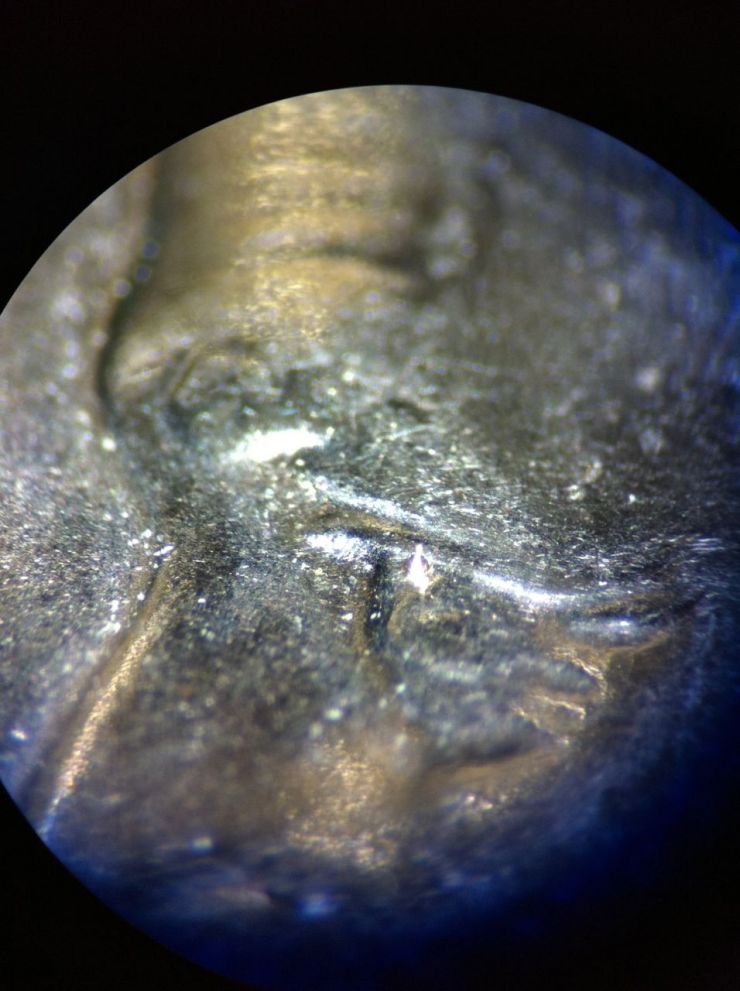

Under normal operations, a 1 mil (25.4 μm) gold wire is threaded through the capillary. A high voltage arc, applied to the tip of the wire by a pneumatic arm, melts the gold and forms a small ball at the tip. The capillary, now carrying the gold ball at its tip, is brought to the surface of the device being studded, and after reaching a threshold of pressure, uses ultrasonic energy to create friction between the ball and the substrate to form a metallic bond. The capillary is then retracted, breaking off the wire and leaving the stud on the pad.